Cladding and weld overlay management

Starting from the 2020.1 version, management of over-thicknesses related to cladding and weld overlay is available in NextGen. This option, initially available for the ASME VIII Div. 1 code, will be progressively extended to the various calculation codes supported by the program.

The option is located among the item properties (File> Item properties), under the "Lining" category. Depending on the type of appliance, vessel or heat exchanger, different input fields are available.

The lining is enabled by selecting the appropriate "Cladding and overlay" checkbox: the insertion of the material used for cladding, the thickness of the cladding, the contribution of the cladding to the resistance of the base material and the thickness of the weld overlay will therefore be requested. As with other parameters in NextGen, the thickness values will be used as the default for the components created but will be overridable for each component. On heat exchangers, the input is replicated for the tube side and the shell side.

The contextual help of these properties contains information about each of them. Basically, the weld overlay is completely removed from the nominal thickness of the component as it is for corrosion, both in design conditions and in test conditions. The same happens for cladding, if the "cladding contributes to base metal resistance" option is not checked. If, on the other hand, this option is enabled, the calculation codes define the amount of the contribution given by the over-thickness. In general, this contribution is proportional to the ratio between the allowable of the base metal and the allowable of the cladding metal.

Once the properties for the item have been defined, the "Lining" category will be displayed in each component. From there it will be possible to choose if the component in question is equipped with lining, of which type and with what thickness.

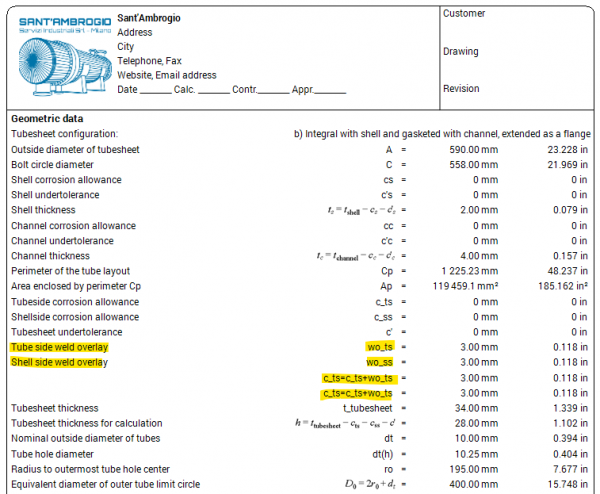

For the tubesheets it is possible to choose the weld overlay over-thickness independently for the two sides.

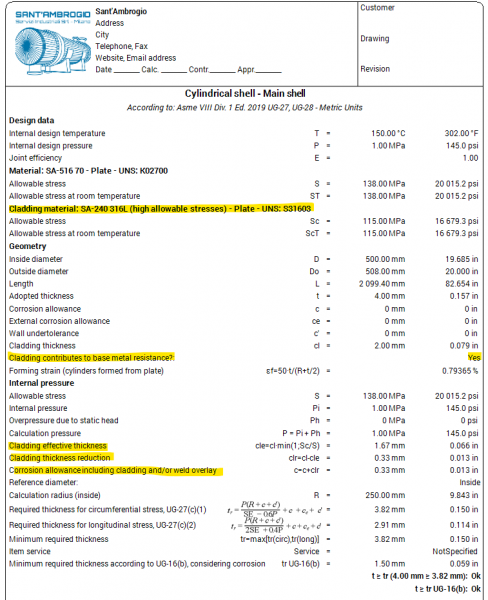

In terms of calculation, and therefore of reports, cladding and weld overlay are calculated and added to corrosion: the corrosion value is redefined, adding the ineffective portion of cladding or the entire value of weld overlay. In the following examples it is possible to see the calculation report of a cylinder with cladding, in which the calculation of the effective and ineffective cladding thickness share, with the sum of the latter to corrosion, and a calculation report of a tubesheet with weld overlay applied on both sides.

Search the documentation

Customer area

Categories

- Getting started

- Frequently asked questions

- Customer support

- Installation

- License management

- Files management

- User interface

- Vessels design

- Heat Exchangers design

- Materials management

- Non-pressure loads

- Calculation report print

- Advanced design

- Versions and changelog archive

- Articles archive from sant-ambrogio.it website

Articles in this category

- How to create a reinforced ring opening (studding outlet flange)

- How to create a jacketed vessel

- How to use a National Annex in EN1991-1-4

- Forming Strains in ASME

- Set liquid level

- Limits on thickness for tubes and cylindrical shells in the VSR standard

- Thread calculation according to EN14359 Clause 5.5.6

- Cladding and weld overlay management

- How to design a stiffening ring against external pressure using NextGen

- Standard flanges and flanges according to calculation code

- How to design a gas cylinder with NextGen