As all the “New Approach” directives, the Pressure Equipment Directive (PED) cannot be applied without standards that are capable to translate into detailed instructions the Essential Safety Requirements contained in the Directive. In fact, the Directive itself doesn’t contain compulsory design, construction or testing details: these details are to be found in the standard, provided, of course, it can be proven that such details comply with the Essential Safety requirements of the Directive: this is in fact the reason why we need “Harmonized standards”, that is, standards giving the so called “presumption of conformity” with the Directive.

The European Commission has entrusted to CEN, the Federation of the European national standardization bodies, the preparation of the harmonized standards. Due to the need to reach a general consensus, there are specific rules to be followed by this organization in order to issue not only harmonized standards for the European directives, but any European standard: the experts charged for the preparation of a standard are working in specific Technical Committees (TCs), and can be appointed only by their national standard organizations (DIN for Germany, BSI for UK, AFNOR for France, UNI for Italy and so on); the three official languages of CEN are English, French and German: all the drafts prepared by the TCs must be available in all these three languages before being presented to the following approval procedure. This procedure consists first in a Public Enquiry, in which each national standard body may approve or disapprove the draft: each standard body has a weighted voting power roughly depending on the number of inhabitants of its own country. In case of approval, it is possible to make comments: the TC who has prepared the draft has the duty of examining the comments, and accept or refuse each comment: however, it should provide a justification for all comments that are refused. The final stage is the Formal Vote, in which the national bodies approve or disapprove, also with a weighted voting procedure, the revised draft, that in case of approval will become a European standard. This procedure is exactly the same for a new standard or for the amendment of an existing standard. Note that after the approval of a European standard all national standards dealing with the same subject must be retired.

Once the preparation of a new standard, or the amendment of an existing standard has been agreed in a specific Technical Committee (that is, a new “work item” for this TC has been approved), for all the preparation and approval steps described above there are specific time constraints, including the time needed for the translation into all the three CEN official languages (although most of the draft are prepared in English, the translation is necessary for the presentation of the draft either to the Public Enquiry or to the Formal Vote): if these time constraints are exceeded, the relevant work item must be cancelled.

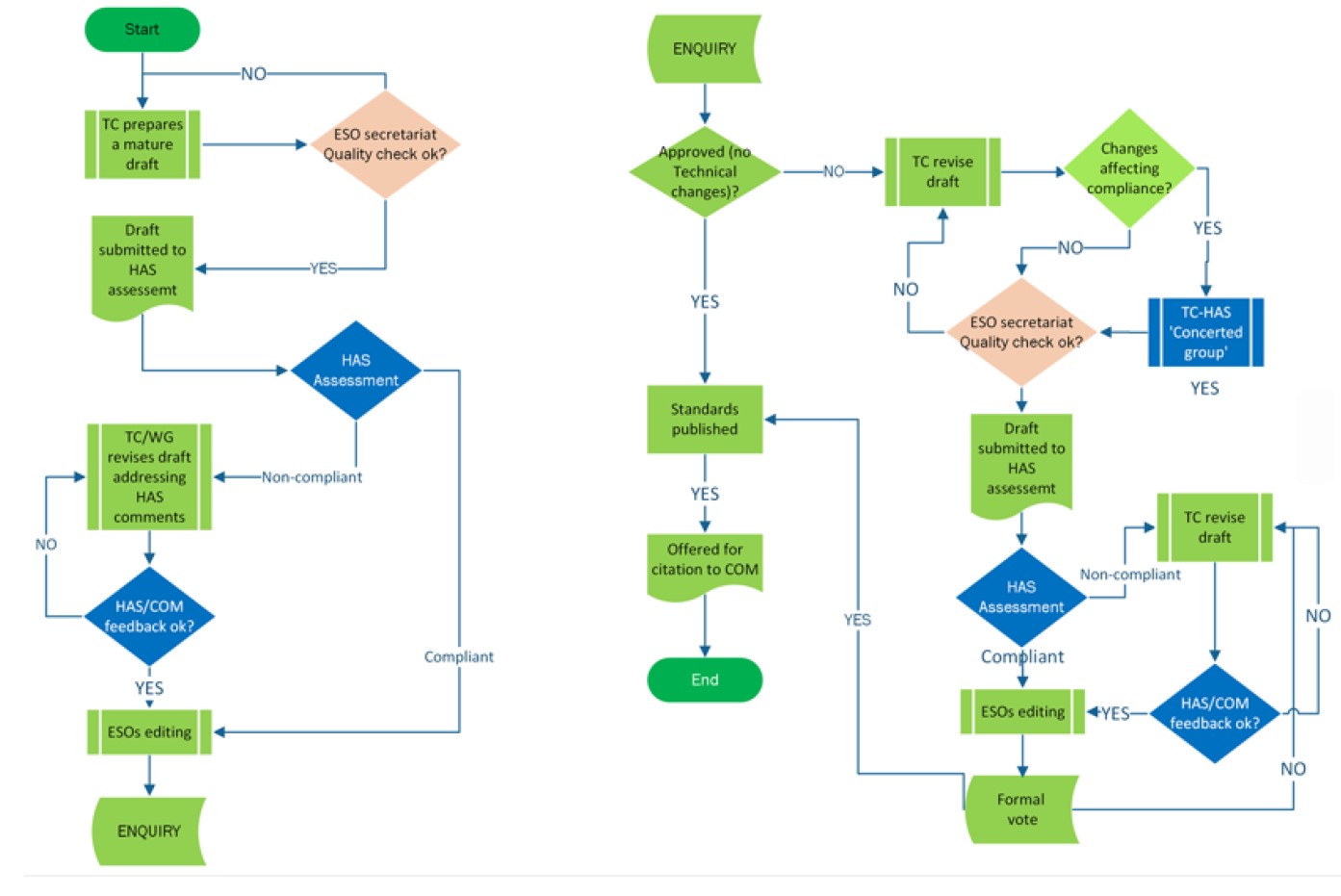

However, the preparation of a harmonized standard (or an amendment of a harmonized standard) has some additional steps, based on the need of an approval of the so-called HAS consultant. What is a HAS consultant (better: a Harmonized Standard consultant)? The HAS Consultant is an independent expert, charged by the European Commission, to verify the compliance of any new harmonized EN (or any new amendment of a harmonized EN) with its relevant directive: only after verification of such compliance, the standard is entitled to be listed in the OJEU (Official Journal of the European Union), thus giving it the right that its use can guarantee presumption of conformity with the directive. It would be too long to come into more details on this subject: whoever needs to have more information on the tasks of the HAS consultant and on the procedures that must be followed to get compliance of a EN with the directive, can find everything in the following link (taken from the BOSS = Business Operating Support System website):

https://boss.cen.eu/developingdeliverables/pages/en/pages/has_assessment_process/

The following figure summarizes the different steps of the procedure:

For the specific case of the Unfired Pressure Vessel standard EN 13445, there is a further complication: a new edition must be prepared every 5 years, while only a single yearly amendment can be prepared every year for each part of the standard. EN 13445 is prepared by CEN TC54, and is composed of many different parts: part 2 for materials, part 3 for design, part 4 for manufacture and so on. Generally, each part is under the responsibility of a specific Working Group of experts. The new procedure is particularly penalizing Working Group 53, who is in charge of part 3: in fact, following the prescriptions of the Pressure Equipment Directive, the idea of the experts of this Working Group has always been to complete as far as possible the calculation procedures, considering not only pressure, but all the possible other loads, such as wind, earthquake, local loads caused by supports: therefore the content of this part was progressively enlarged, so that the 707 pages of the first Edition (2002) have been increased to 874 in the Edition 2021, while the first amendment of this edition is composed of 206 additional pages. Note that this amendment still belongs to the previous Edition 2014, and therefore it contains subjects on which the discussion started several years ago: all these amendments have already been discussed and implemented with the comments of the Public Enquiry, but could not be brought to the Formal Vote, which will possibly take place this year, provided WG53 will be able to answer all the possible comments raised by the HAS consultant. But what will happen for the future yearly amendments? We have already a draft of a further Amendment, which contains modifications carried out by different experts on several Clauses and Annexes: considering that it is not possible to discuss each modified clause separately, because according to the new way of working only a single amendment of part 3, containing all possible modifications, can be brought to the approval procedure, if somebody will raise a problem on a specific clause, the only possible solution is to skip the modifications of this clause in order to save all the remaining modifications.

Moreover, the experience of the past years has proven that in order to build a new standard the experts in charge of its preparation must be in complete agreement on the theory on which the standard is based: otherwise, considering the constraints imposed by the CEN rules, all the consequent discussions will cause unacceptable delays. In this respect it is clear that, before asking for the opening of a new work item, the matter must be discussed in a task force belonging to an organization which is free from such constraints. This organization was in fact created by the European Commission already in 1997 and was called EPERC (European Pressure Equipment Research Council), considering the positive experience of the similar organization existing in USA (PVRC = Pressure Vessel Research Council). The Task Forces of EPERC started to work on many different subjects, for which a research activity was needed, and for which the new Pressure Equipment Directive was requiring new and advanced standards: since membership of EPERC was free of charge, many experts, belonging to universities, research centres, pressure equipment users and manufacturers, engineering companies and notified bodies started to take part in the work of these Task Forces. Many interesting bulletins and research reports were prepared in the first years of activity, dealing with Design by Analysis, Flange Leak Tightness, new advanced steels, etc. Of course, the costs of managing the organization were certainly not negligible: but at the beginning they were supported by the European Commission, who appointed the Joint Research Centre of Petten as secretariat of EPERC.

However this support could not last indefinitely: and when it came to an end, JRC was replaced by other entities, which however sooner or later realized that they could not go on spending money in the organization of meetings and seminars without a corresponding income: at the end, the real advantage was for the companies to which the experts belonged, because in the context of EPERC activities there was the possibility of organizing research projects financed by the Commission, carried out by joint ventures composed by organizations of different countries: these projects, identified by different acronyms, marked important steps in Pressure Equipment technology as in Pressure Equipment standardization (Design by Analysis, PERL, ENVELOPS, Comparative Study, etc).

However, the problem of the cost of the secretariat (generally called “Operating Agent”) was still there. In 2011 the Board of Directors decided to make an important step forward, transforming EPERC (a simple “de facto” organization) into EPERC-AISBL, a not-for-profit organization according to the Belgian law. Which advantages could be obtained in this way? The idea was to require a yearly contribution from the members: an association fee (relatively low for individual experts, much higher for companies), to be used for the management of all the Task Group activities. Unfortunately, the time and the bureaucracy needed for the creation of the AISBL caused a stop in all EPERC activities. During this stop, many experts of the former EPERC forgot its existence: and when somebody told them that, in order to restart the activity, they had to pay something, they simply disappeared. Sometimes also important organizations were reluctant to pay some money that they could hardly justify before their management (already worried by the fees required by their national standardization bodies engaged with the work in CEN): so a few experts of these organizations preferred to become themselves individual members of EPERC-AISBL, having their membership fee paid by their companies; while the heavy bureaucracy and the heavy costs tied to the management of a Belgian AISBL (need to translate into French all the documents, need for a fictitious postal address and telephone number in Belgium, presence of a Belgian Notary and a Belgian Bookkeeper, and so on) was discouraging all the further operating agents of EPERC-AISBL, which, after some years of positive work, preferred to resign and leave this task to someone else.

Nevertheless, EPERC-AISBL was able to organize many successful events: the last one was the Conference organized in Roma in 2019. However, the Covid 19 caused a stop of all Task Group in presence meetings and seminars, so that all the TG meetings in the subsequent years have been organized via internet. In 2022 and 2023, after the resignation of the last operating agent, the role of the Operating Agent was supported by the Board of Directors. At the end, having realized that it was not possible to go on in that way, the last BOD decided to dissolve the AISBL, which, having paid all the possible creditors, was definitely dissolved in the General Assembly of October 10th 2023. The remaining funds (around 500 Euro) were enough to assure the continuation of the web site: therefore, as a last Chairman of the AISBL, I took the engagement to use them for this purpose.

What is really fundamental, is the collaboration between the Technical Committees of CEN and the Task Groups of the new EPERC: in other words, the work of EPERC must be oriented to the needs of CEN. Just to make an example, WG53 of CEN TC54 (in charge of Unfired Pressure Vessel design and calculations) has received from many experts the request to integrate into EN 13445.3 the possibility of a flange design based on an acceptable leak rate, considering the work already done in TC74 (Flanges) who has prepared the standard EN 1591-1. However EN 1591-1 has provided only two types of bolted assemblies: flange to flange and flange to cover, while in order to make a complete standard we need also to consider flanges bolted to tubesheets and tubesheets of removable bundles, which are generally placed between two flanges bolted together, with different design conditions on each side. Moreover, one of the main problem of the method in EN 1591.1 is the need to consider the actual characteristics of a specific gasket supplied by a specific manufacturer: this will oblige the designer to select the manufacturer and the gasket also in case of a preliminary calculation made at the offer stage, while, on the other hand, it may be an unacceptable constraint for the maintenance of a process plant. Well, in 2022 Task Group 3 of EPERC (Flange Leak Tightness) had started a study on the behaviour of a given bolted assembly using different gaskets, supplied by different manufacturers, in order to check the possibility of creating a table with standard gasket characteristics having as a variable also the “tightness class”, that is, the acceptable leak rate.

Of course this is only an example of the kind of activity that EPERC could perform: this activity is generally called “prenormative research”, and in the Unfired Pressure Vessel standard EN13445 there are many other cases in which it has been proven that the actual organization of CEN is not able to include this activity in the preparation of a new standard.

Together with the last BOD of the former AISBL, we are now studying the possibility of creating a new not-for-profit “de facto” association, possibly free of charge for all the individual members, except for a ticket to be paid in case a member wishes to take part in a particular Task Group meeting; on the contrary, company members will pay a yearly association fee, giving them the possibility of an unlimited participation of their collaborators to all the TG meetings. In any case, all the members will obtain the credentials to access the “members area” of EPERC, containing all the procedings of the past conferences, meetings and seminars, as well as the minutes of all the TG meetings. Of course, this is just a proposal, to be discussed first of all with the members of the former AISBL, but any alternative proposal could be considered.

In any case, whichever will be the rules of the new EPERC, what is important is to find a suitable “Operating Agent”: an entity (university, research institute, private company, notified body) which can use the money collected with any source of possible income for the organization of events with a large participation of experts. We will be glad to examine all possible candidates to the role of Operating Agent.

As I said before, the web site of EPERC-AISBL is still open:

and the former members of EPERC-AISBL are still able to access the “Members Area” and see all the historical documents, studies, projects, conference procedings, minutes of Task Group meetings created up to now. If somebody needs limited time credentials to enter the “Members Area” and examine all this material, under “contact us” you can require such credentials and forward your opinion and possible advice.

Fernando Lidonnici

Convenor of WG53/CEN TC54

(Last Chairman of EPERC-AISBL)

Milano, February 8th, 2024