In the 19th century, when the first steam boilers started to be designed and fabricated, the most important problem that the designers had to solve was the determination of the allowable stress of the carbon steel plates used in their fabrication. The allowable stress (or, using the European terminology, the nominal design stress) of the material had to be based on a characteristic expressing the resistance of the material when it was subject to a load causing a specified stress. At that time the only characteristic of the material that was normally considered was the tensile strength at room temperature: this characteristic has the advantage to be easily determined, to be relatively constant in the range of temperature used for the boilers (150-200 °C maximum), and to be constant with time: therefore, in order to obtain the allowable stress, it was considered sufficiently safe to apply to the tensile strength a safety factor of 4 to 5: and since the stress in a shell is directly proportional to the pressure, supposing that the explosion of the shell would take place when the material would reach its tensile strength, these values of the safety factor, in theory, would have guaranteed a design pressure 4 or 5 times lower than the bursting pressure.

With the progress of technology, there was the need to consider higher service temperatures: which shifted the attention of designers to another material characteristic: the yield strength at temperature. Since this characteristic is progressively decreasing with temperature, most pressure vessel standards provided an allowable stress which was the minimum value between the tensile strength divided by the said safety factors and the yield point divided by another safety factor, generally between 1,5 and 1,6. With this criterium the minimum thickness of a vessel made of carbon steel remained practically controlled by the tensile strength up to temperatures of 200-250°C, until somebody in Europe decided to give less importance to the tensile strength, thus decreasing the original values of 4-5 to lower values, between 2 and 3.

Of course this tendency had an influence also on the American standards: so that, at the beginning of the 21st century, the traditional factor of 4 for Carbon and Low Alloy steel in Section I and section VIII division 1 of the ASME Boiler and Pressure Vessel Code was reduced from 4 to 3,5, always keeping the 1,5 factor on the hot tensile strength. But at that time there was already another American Standard, division 2 of Section VIII, used for vessels working at higher pressures (the pressure limit for division 1 was 3000 Psi). This standard also considered, together with the traditional design by formulae, advanced analytical design methods: more stringent requirements on manufacture and testing methods, permitted the use in this standard of a still lower safety factor on tensile strength: 3 instead of 3,5. The influence of the European standards, together with the coming into force in Europe of the Pressure Equipment Directive, in 2007 caused a further decrease of the safety factor from 3 to 2,4 in ASME Section VIII division 2, thus using the recommended value provided by the European Directive, also copied in the harmonized EN standard 13445-3.

At this point it is worthwhile remembering the discussions made in the European Commission during the preparation of the Pressure Equipment Directive. This directive was made following the so called “New Approach”, that is, the idea that all European Directives are not fabrication standards, but binding laws of the European Union: therefore they should not contain precise figures, that could change with the evolution of technology, such as safety factors on material characteristics, welding efficiencies and so on: they should only contain “Essential Safety Requirements”, leaving the numerical prescriptions to the harmonized EN standards, which could be changed without the intervention of the European Parliament. The harmonized standards must be prepared by CEN (the European Standardization Committee) in conformity with the Directive, and therefore they must be capable to guarantee the “presumption of conformity” with it. Of course, the application of this principle was not at all easy: how is it possible to guarantee that the nominal design stresses of the materials are sufficiently safe if we do not specify in the Directive itself the safety factors to be used?

As in many other cases, a compromise solution was finally found: Clause 7 of Annex I to the Pressure Equipment Directive contains the most important numerical values needed for the design; however, at the beginning of this Clause, there is the following statement: “The following provisions apply as a general rule. However, where they are not applied, including in cases where materials are not specifically referred to and no harmonized standards are applied, the manufacturer must demonstrate that appropriate measures have been taken to achieve an equivalent overall level of safety.” In other words, the Directive doesn’t prescribe the values of the safety factors: only recommends them, but requires the presence of “equivalent safety measures” in case they are not used: therefore, the value of 2,4 on the tensile strength may be waived if such equivalent measures have been provided. But what is the logic behind the value of 2,4? A big discussion took place among the experts of WG53 (Design and Calculations) of CEN TC54 during the preparation of the first edition of EN 13445, the European Unfired Pressure Vessel standard. We were in the last decade of the 20th century, the Pressure Equipment Directive was still in preparation, but CEN was already working on the relevant harmonized standards: in fact, the value of 2,4 provided by the Directive was taken from the standard (and not vice versa), because of the said discussion. The discussion concerned the value of the safety factor on the tensile strength, which was different in every one of the national pressure vessel standards: moreover, one of the most important pressure vessel standard (the German code AD Merkblätter, now AD 2000) did not take into consideration at all the tensile strength: in this standard the nominal design stress was only based on the yield point at temperature, with no consideration at all for the tensile strength.

Note that this peculiar characteristic of the German code has given origin in Germany to a special class of steels: the fine-grained high strength steels (now covered by the material standard EN 10028 part 3), in which the yield point is very high and close to the yield strength. These steels, because of their chemical analysis which guarantees a particular refinement of the grains and therefore a very good ductility and impact properties, when used with the German pressure vessel code, have nominal design stresses around 300 MPa. Such design stresses could never have been reached with the limitation of a safety factor of 2,4 on the tensile strength. Use of these steels is very useful in the fabrication of high diameter spherical LPG tanks, that, because of their huge dimensions, must be fabricated assembling and welding in place spherical segments: it is therefore very important to reduce their thickness, in order to avoid local heat treatments very difficult to be carried out in place.

For this reason, the German experts were against the introduction of a safety factor on the tensile strength: and they also argued that the basic idea that such safety factor would represent the ratio between the bursting pressure and the design pressure was completely wrong. In fact, mentioning the results of several pressure tests carried out in Germany, they could demonstrate that the tensile strength of a monoaxial tensile specimen has nothing to do with the real value of the tensile strength causing the failure of the wall in a cylinder or in a sphere under pressure, where the stress is not at all monoaxial, but it is distributed in all directions.

Therefore, considering the content of the already mentioned Clause 7 of Annex I, a compromise solution was finally found: the so called “alternative route”: in a few words, provided that alternative safety measures are taken (more stringent requirements on design, manufacture and testing), the safety factor on the tensile strength can be lowered from 2,4 to 1,875 (which, at the end, simply means not to consider the tensile strength at all). Note also that EN 13445-3 permits design by analysis not only with the elastic approach, in which the analysis is carried out supposing that the material is fully elastic also beyond the yield point; but also provides the use of limit analysis, which better represents the behaviour of the material under increasing load: fully elastic only up to the yield point, then, perfectly plastic, with a progressive increase of strain while the stress remains constant and equal to the yield point. It is clear that with an elastic analysis the design parameter is always the nominal design stress, possibly determined also by the tensile strength, but different according to the various stress categories (primary, secondary, peak, general, local, membrane, bending, etc.); on the contrary, with a limit analysis all the areas where the yield point has been reached must be evaluated considering the strains and not the stresses, because in these areas the stress is constant and equal to the yield point, and therefore without any further consideration of the tensile strength.

It is a fact that, even if the harmonized standard EN 13445-3 is always more used, the Pressure Equipment Directive also permits the use of other Pressure Vessel standards, provided it is possible to prove that they comply with the Essential Safety Requirements of the Directive: therefore standards like AD 2000 in Germany, CODAP in France and PD5500 in UK are always used, even if they consider different safety factors on the tensile strength (or no safety factor at all, as in the case of AD2000): this because each one of them is able to provide some kind of alternative measures as prescribed in the already mentioned Clause 7 of Annex I.

However, even the procedures imposed by CEN and the European Commission are rather heavy and time consuming (approval of any amendment of the standard in a Public Enquiry, to be launched after translation into the three official languages of CEN – English, French and German, compulsory answers to all the comments made during this Enquiry, supervision of an expert of the Commission certifying that all the ESRs of the Directive have been properly considered, Final Formal Vote), EN 13445-3 is progressively becoming a well-structured design standard, covering all the possible load and service situations.

Also in USA something is progressively moving, even if it is not always completely clear which is the goal of the continuous evolution of the Boiler and Pressure Vessel Code. As already explained, the value of the safety factor on the Tensile strength is progressively decreasing: now 3,5 with ASME VIII division 1, lowered from 3 to 2,4 in ASME VIII division 2 Edition 2007; partially modified in the 2017 Edition of this standard, where a second class of vessels has been introduced, again with a coefficient on the tensile strength of 3.

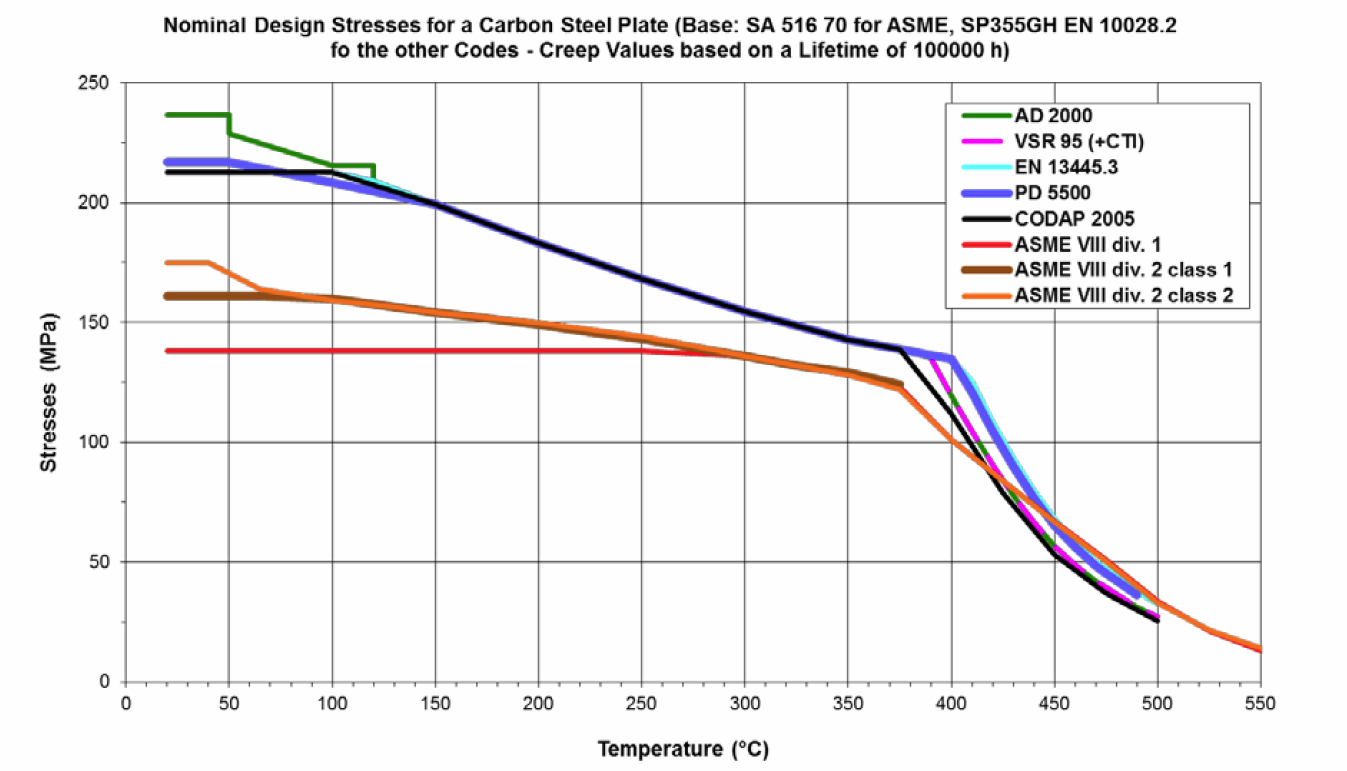

The idea was to allow manufacturers already authorized to build ASME VIII division 1 vessels to fabricate also vessels in accordance with class 1 of division 2: however, class 1 vessels could not be used at temperatures below the creep range and in case a fatigue analysis was required. The figure (referred, for the American standards, to Carbon Steel SA 516 70) shows the difference between the nominal design stresses of all the ASME VIII standards (division1, division 2 class 1 and division 2 class 2): it is clear that the difference between class 1 and class 2 vessels is limited to temperatures lower than 100 °C. The comparison with the nominal design stress obtained by the European standards using an equivalent EN material (P355GH EN 10028-2), proves also that the advantage of the European standards, even when they consider the same safety factor 2,4 on the tensile strength, doesn’t depend on the safety factor itself, but on the higher yield characteristics of the European materials; which is logical, if you consider that the great majority of the vessels in USA are designed in accordance with division 1, that is with a safety factor of 3,5 on the tensile strength, always controlling up to temperatures of 250°C: in this way, there is no advantage in specifying materials having a higher yield point.

Considering that the fabrication and testing requirements of ASME VIII division 2 are the same for class 1 and class 2 vessels, and that many design methods of ASME VIII division 1 have progressively been aligned with the same methods of division 2, in the last edition 2025 of ASME Section VIII division 2 class 1 vessels do not exist anymore. In any case, also in components for which the design formulae of division 1 are not yet the same of division 2, it is always possible to use the formulae of division 2 in a vessel designed to division 1, provided the nominal design stresses used are the nominal design stresses of division 1. Considering this evolution, it is very well possible that in the next years the safety factor on the tensile strength in ASME VIII division 1 will have a further reduction from 3,5 to 3.

In any case, although fine grained high strength steels are considered by ASME Section II-D for use with ASME VIII division 2, keeping the present limitation of 2,4 on the tensile strength the advantage of using such materials with this standard remains considerably limited. Just to make an example, a pressure vessel plate of SA 537 class 2 with a thickness of 65 mm at room temperature has an allowable stress of 229 MPa, clearly limited by its tensile strength of 552 MPa and not by its yield strength of 414 MPa. If used with EN 13445-3, considering the alternative route, its allowable stress would be 276 MPa, that is, 20% higher: and the corresponding thickness of a pressure vessel would be of course 20% lower.

At the end, the idea that the safety factor on the tensile strength is a measure of the ratio between the bursting pressure and the design pressure seems to be deeply rooted in the American standards. Or shall we expect something new for the future?

Fernando Lidonnici

Convenor of WG53/CEN TC54

Milano, October 6th, 2025